ROMI DCM 620-5X Hybrid

Additive Manufacturing (3D Metallic Printing)

Presentation

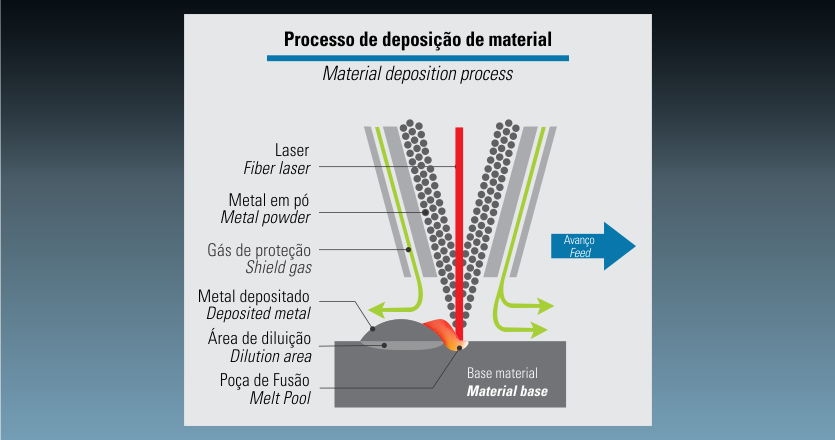

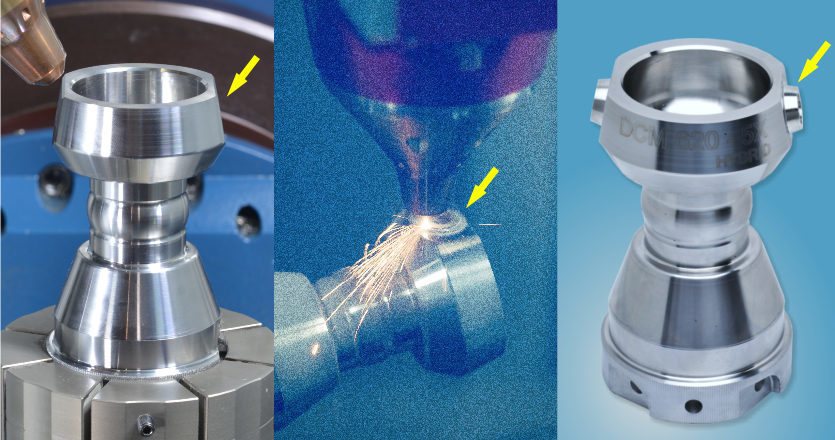

The ROMI DCM 620-5X Hybrid 5-axis Vertical Machining Center combines machining operations and additive manufacturing (3D metallic printing), allowing the addition of different materials in complex profiles. Materials such as Inconel and Stainless Steel can be added in the exact amount to achieve the desired profile, and later machined, obtaining great savings in the use of these high-cost materials.

Strategically, it is possible to add materials of greater resistance in certain areas of greater wear, increasing the durability of the parts or components, as in stamping tools. The laser head that performs the melting of the powdered material can also perform engraving operations.

Another important application is the repair of molds and dies, where the material can be deposited in the damaged region and immediately machined, reducing the repair time even in complex profiles. In this case, there will be low-temperature transmission to the mold, avoiding possible thermal cracks.

Main Technical Features

| ROMI DCM 620-5X HYBRID | ||

|---|---|---|

| Spindle taper | ISO | 40 |

| Speed range | rpm | 15 a 15.000 |

| Rapid traverse (X / Y / Z axes) | in/min | 1,1417 |

| Superior table travel (X axis) | in | 24 x 24 |

| Installed power (Hybrid Headstock) | kVa | 50 |

| Wave Leight (Hybrid Headstock) | nanometro | 1,070 |

Consult an expert

Do you need more information about this product? Find here the nearest specialist or send a message.