ROMI D Series machines are extremely versatile for several machining applications. They are designed to operate in high production sites as well as in tool rooms. Our D Series machines offers high rigidity even under severe machining conditions and present thermal and geometric stability ensuring great performance, precision and productivity.

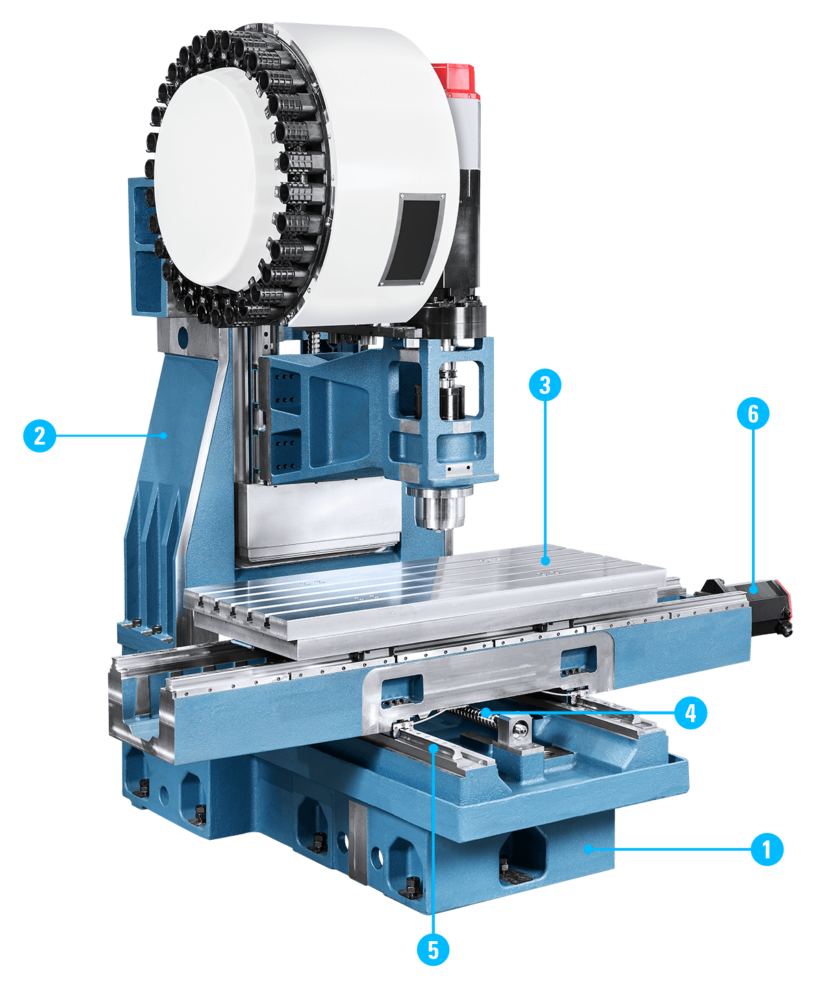

1 | Monoblock BASE made of cast iron, designed to absorb vibrations, provides parts with excellent finishes, longer machine life and longer lasting cutting tools.

2 | COLUMN: Dimensioned to support the headstock assembly with excellent geometric stability for the whole assembly.

3 | The TABLE is supported on linear guides, with multiple T-slots for mounting and securing devices. Designed to supprt heavy parts with excellent stability.

4 | BALLSCREWS: Hardened and ground with pre-loaded nuts provide high rigidity and high accuracy in both positioning and repeatability of axes.

5 | LINEAR ROLLER GUIDES (ROMI D 800, D 1000 and D 1250). Enable fast displacements with precision and high accelerations due to low friction coefficient between rails and blocks.

6 | Brushless AC SERVO MOTORS are directly coupled to the ballscrews and have integrated absolute encoders, which transmit the movement directly, providing accurate positioning and excellent repeatability of axes.